Developing a digital research infrastructure for the manufacture of dental equipment (DiTeDe)

Duration of the project

Source of funding

Renewable and Competent Finland 2021-2027EU Regional and Structural Policy Programme, European Regional Development Fund (ERDF), Uusimaa Regional Council

Total funding

300 000 €

The project, co-funded by the European Union, will develop methods for the fabrication of dental prostheses to strengthen digitally fabricated prostheses and use digital imaging and virtual reality in the fabrication process.

Through this project, the development of manufacturing technology will bring added value to local oral health care providers. The project will be carried out by the higher education institutions of the Turku campus area (University of Turku and Turku University of Applied Sciences), which will work together to develop the oral health research infrastructure and a centre of excellence in dentistry, providing know-how to companies and public actors in the Southwest Finland region. The future cluster of excellence will serve the whole country. The project will also cooperate with the Turku Area Centre of Excellence for Compounding (TICAM).

The potential of digital production methods in dental care has grown very rapidly, but the overall picture is fragmented. The multiplicity of equipment manufacturers and manufacturing technologies makes it difficult to exploit them. Dental prostheses are made in collaboration with several players. A prosthetics team consisting of a dentist and a dental technician must have equipment from the same manufacturer (facial arch, etc.) in order to produce digital prostheses in collaboration. The use of digital imaging techniques is not yet as widespread as it could be. For example, the potential of virtual reality is still under-utilised in the production of dentures.

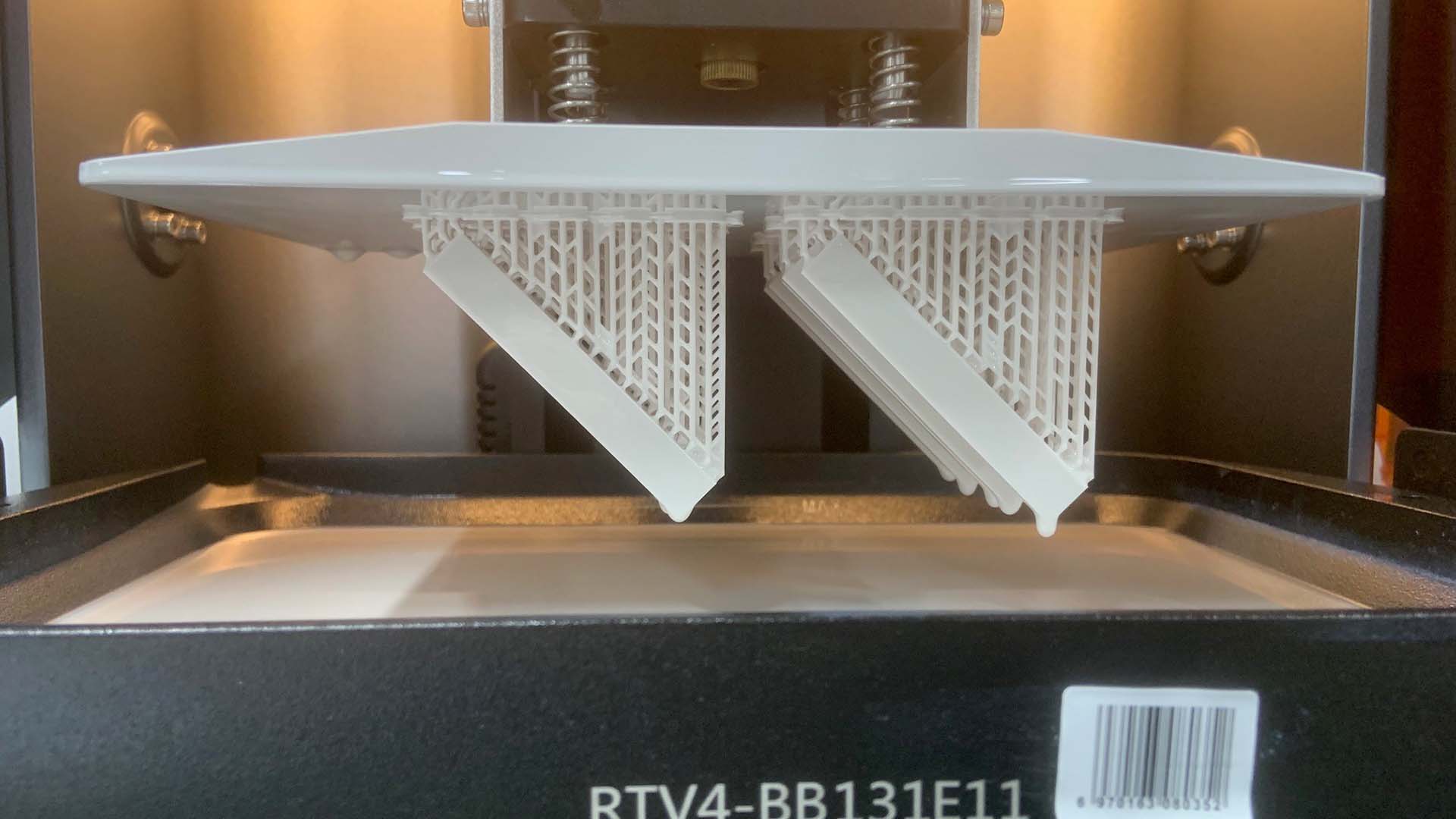

Combining VR technology with digital prosthetic design is a major development in this project. It could improve the flow of information between the dentist and the dental laboratory. The project will experiment with new imaging modalities and methods for visualising prostheses. The introduction of these is expected to have a positive impact on the quality of dentures. At the same time, methods will be developed to make dentures stronger. We are developing digital fabrication methods for making reinforcements. The project will also test the quality of the reinforcement methods developed using mathematical modelling.

Contact us

Partners

- University of Turku, Department of Dentistry, Clinical Biomaterials Centre (TCBC)

Meet the research team

-

Research teams

Suun terveys

See all our projects

We carry out nearly 200 RDI projects every year, in collaboration with working life and international partner networks.