Solar Module Laboratory

We offer a reliable domestic solar module testing service. Our solar module laboratory is the only accredited solar panel testing laboratory in Finland.

Turku UAS’ solar module laboratory offers unique, FINAS-accredited solar panel testing in Finland (PV module power and integrity testing). The laboratory’s services cover reliable measurements of panel performance and durability according to international standards. The laboratory tests, among other things, the electrical performance of solar panels and the effects of environmental conditions, ensuring the quality and longevity of the panels.

Our services are based on the evaluation of equipment already on the market, completed or under development, in scenarios corresponding to their future use. In addition to equipment testing, we also offer consultancy services during the design and development phase.

PV module power and integrity testing

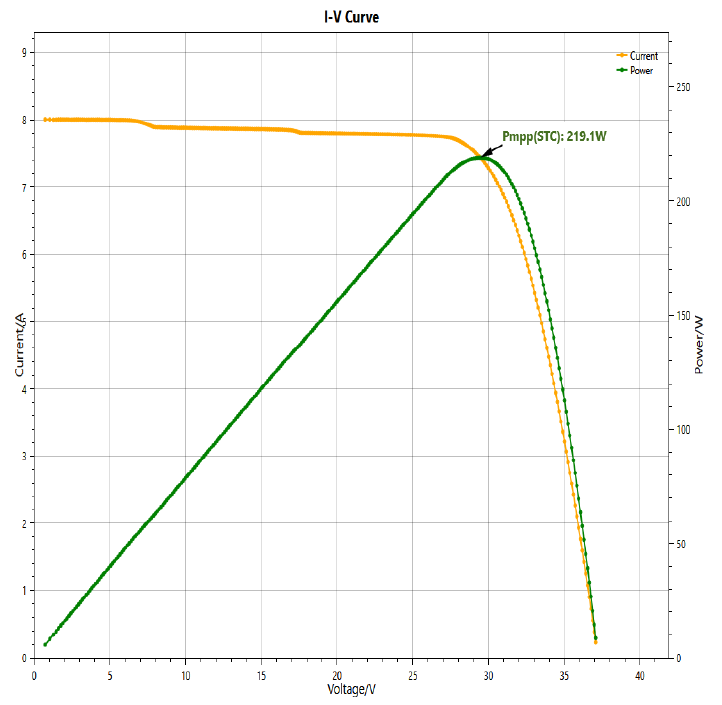

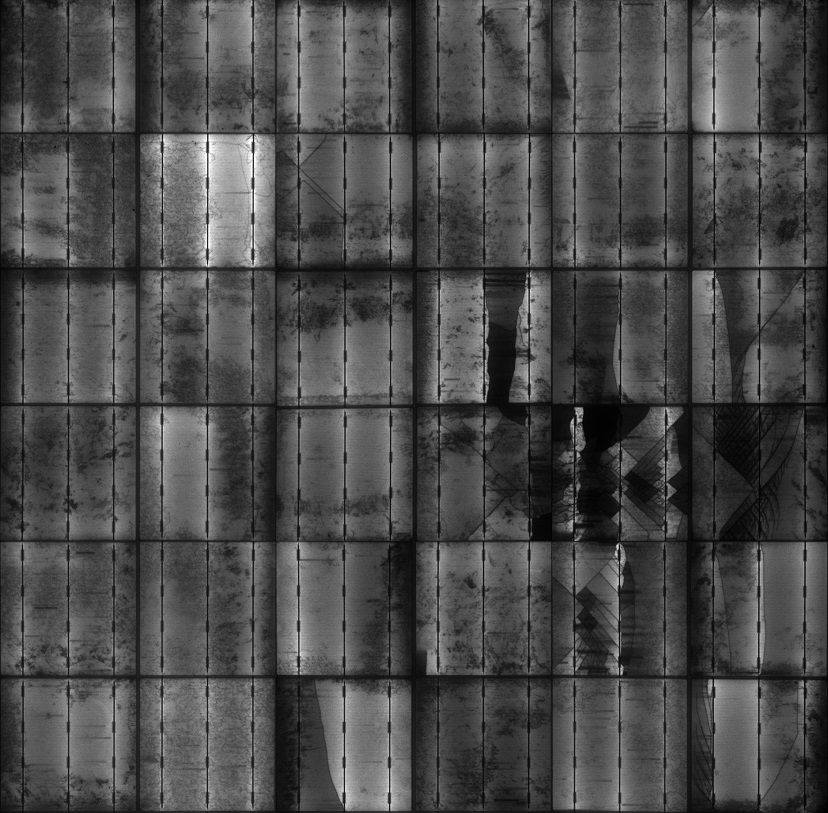

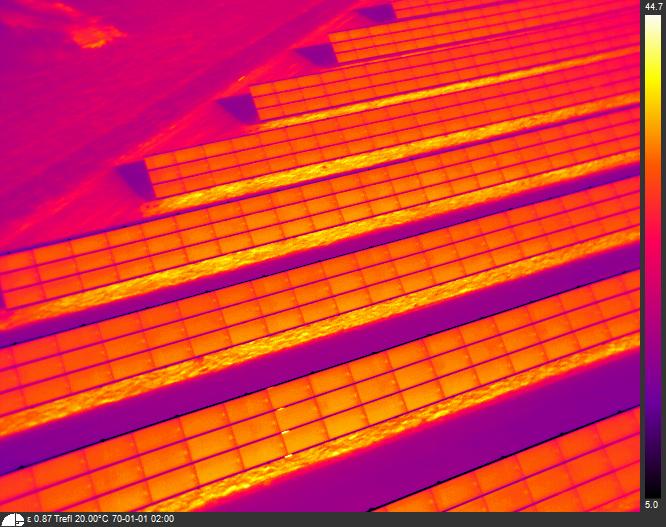

Photovoltaic (PV) module power and integrity tester is important part of quality control for PV modules. The inspection systems provides electroluminescence inspection, IV-curve measurement using an LED flasher, infrared imaging HiPot-Testing and UV-fluorescence image acquisition. It is a powerful tool for detecting microcracks and other defects that may not be visible through visual inspection. Even on-site. PV module power and integrity testing is FINAS accredited.

Power Measurement & characterization

- According to the IEC60891

- Power in STC conditions

- IV-curve

- Electrical characteristics

Electroluminescence Imaging

- Cell mismatch, hotspots

- Cracks & micro cracks

Our test equipment

Mobile Solar lab – Long Pulse LED Flasher

- A+A+A+

- 200 ms pulse length

- Electroluminescence imaging

- Air conditioned

H.A.L.M. – Long Pulse Xenon Flasher

- 70 ms pulse length

- A+A+A+ rated

- Temperature controlled

Benefits for the customer

- Quality assurance

- Minimizing technical and financial risk

- Objective third-party measurements

PV module mechanical load testing

PV Module Mechanical Load Testing (MLT) is a critical aspect of quality assurance for photovoltaic (PV) modules. This process validates the durability of solar panels by ensuring they can endure external mechanical forces, such as wind, snow, and human handling, without compromising their structural integrity, safety, or energy efficiency.

Solar panel manufacturers usually specify a mechanical load rating for their modules, outlining the type (static or dynamic) and magnitude of external forces the panels can tolerate. However, if this information is unavailable or if there’s a need to verify whether a particular panel or batch complies with industry standards, our MLT-device can accurately perform these tests.

To identify potential damage or changes resulting from mechanical stress, we also employ various testing methods. One method is electroluminescence (EL) imaging, which is highly effective for detecting microcracks and hidden defects that may not be visible during a standard visual inspection.

PV module light soaking

PV Module Light Soaking Testing is a vital procedure used to assess and enhance the long-term performance and reliability of photovoltaic (PV) modules. Solar panels often experience performance fluctuations in the initial phase of operation, during the first or second year. The testing method simulates prolonged exposure to sunlight, allowing for the stabilization of module performance before field deployment. This process helps to better predict how the panels will perform over their operational lifespan.

By utilizing advanced testing equipment and controlled lighting environments, we can provide reliable, data-driven insights into the power output and durability of PV modules post-light soaking. This allows manufacturers, developers, and operators to make informed decisions regarding module quality and long-term energy production.

PV plant field testing

PV Plant Field Testing is essential for verifying the real-world performance and reliability of photovoltaic (PV) systems. No matter what the size or placing of the PV plant is, we offer comprehensive on-site testing services to assess the functionality, efficiency, and safety of PV plants under actual operating conditions.

Our corporate customers can use the results of the testing, for example, in negotiations or in problem situations to clarify the compliance of products. This helps companies to manage financial risks.

Samuli Ranta, Research Officer, New Energy Research Group

Contact us, let’s discuss more

Each partnership is structured differently. Tell us what kind of problem you are looking for a solution to. We’d love to hear from you.

Our customers: PV plant owners, EPC contractors, wholesalers, import companies, module manufacturers

Price: Services are tailored to the client’s needs and priced on a case-by-case basis.

Location: Our laboratory is located in Kupittaa kampus area.

First in Finland to receive FINAS accreditation

In 2024, history was made as Turku UAS’ Solar module laboratory became the first accredited solar module test laboratory in Finland. Our PV module power and integrity testing is FINAS accredited. Accreditation is a procedure based on international criteria that allows the competence of an operator to be reliably verified.

With this certification, we continue our commitment to supporting the renewable energy industry by delivering accurate and dependable results that contribute to the long-term success of solar energy projects in Finland and beyond.

FINAS, Finnish Accreditation Service, is the national accreditation body and it is a unit of the Finnish Safety and Chemicals Agency, Tukes.

Experts behind the services

The New Energy Research Group focuses on new energy production methods, decentralised energy systems and energy storage, and sustainable transport. Our experts are responding to the challenges of the energy transition through research and development.