Research group

Manufacturing Engineering

Our research team focuses on solving problems in the manufacturing industry. We work in RDI cooperation with industry, universities and universities of applied sciences.

The RDI activities of our research group focus on five priority areas:

General manufacturing technology: we research and develop manufacturing techniques for mechanical engineering, and industrialise new manufacturing techniques. Our research topics include machining, sheet metal working techniques and assembly. We are also studying how to increase the use of robotics and automation in manufacturing and how to overcome the constraints of use.

Welding and joining technology: we focus on developing joining processes and looking at joints through quality, design and cost. We also look at joints from the point of view of strength, mechanical properties and materials engineering. We also consider the impact and challenges of automation in manufacturing and, in particular, the serial production perspective on joining technologies.

Manufacturing quality and economics: we look at manufacturing production methods from a broader perspective. From a qualitative perspective, we focus both on improving the quality performance of processes and on monitoring manufacturing quality, as well as on the use of quality data to control the manufacturing process.

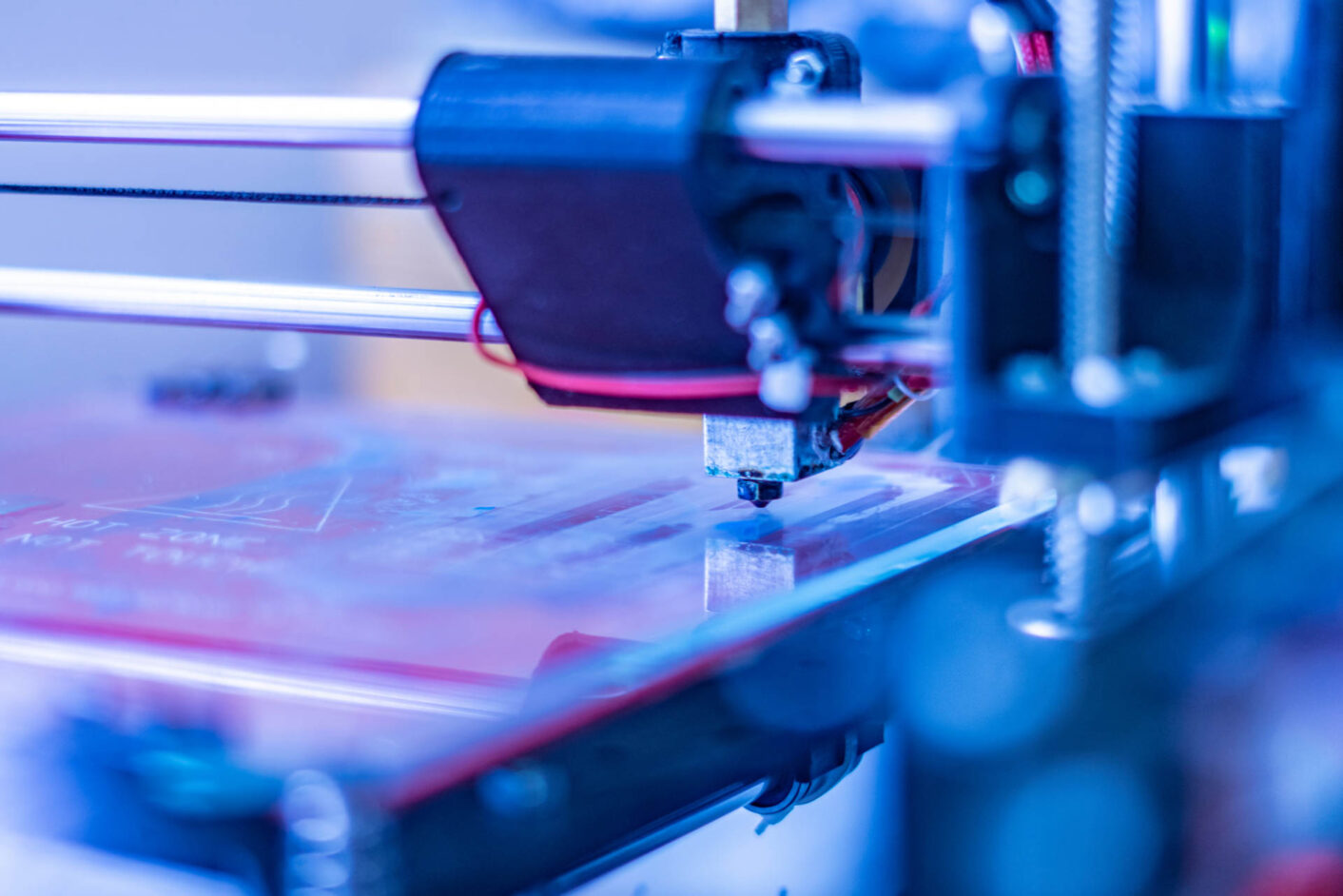

Additive manufacturing: we will look at the potential of additive manufacturing to produce new types of products and develop these manufacturing techniques. We will provide information on the possibilities and constraints of additive manufacturing to produce different 3D shapes, as well as information on the material properties of the manufactured material in the application. This will enable the product designer to make the right decisions at the design stage.

Manufacturing technologies for electrical energy storage: we aim to meet the challenges of manufacturing technologies and develop production methods for battery technology for electric vehicles and non-road machinery. These research activities support the battery cluster in Southwest Finland. We aim to answer questions that are particularly important for battery manufacturing, such as electrical safety in manufacturing, manufacturing productivity, quality management and assurance.

We aim to respond to the problems of the manufacturing industry by developing different areas of manufacturing technology.

Saariluoma Heikki, Lecturer, Research Group Leader

Our Experts

Network and partners

- Meyer Turku

- Sandvik

- University of Turku

- Valmet Automotive

Strong project skills

Turku University of Applied Sciences’ Project Office offers support and guidance throughout the life cycle of an RDI project. Our project experts have years of experience and strong expertise in national and international funding programmes. We have more than 200 projects running every year, and our RDI activities have received more than €10 million in external funding.