Mathematical modelling has many practical applications. Rabia Altunay, a researcher in the Computational Engineering and Analysis (COMEA) research group at Turku University of Applied Sciences, is interested in the medical applications of mathematical modelling in her PhD thesis at LUT.

Published:

Edited:

Text: Martti Komulainen

Photos: COMEA and Oral Health Research Groups, Turku UAS, Martti Komulainen (portrait)

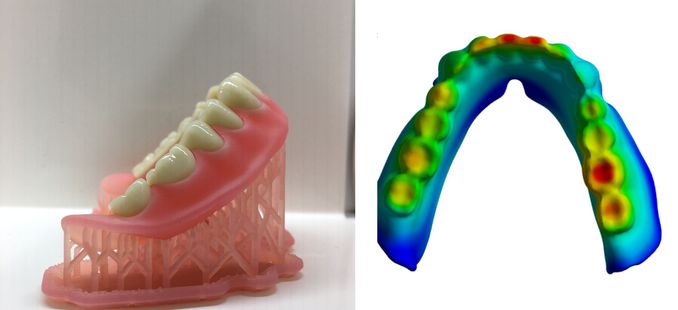

Recently, Rabia Altunay and her research colleagues presented a study at the SIAM (Society for Industrial and Applied Mathematics) conference on the optimal strength structure of 3D printed dentures. In the simulation, the virtual counterpart of the modelled prosthesis, a digital twin, was subjected to forces that mimic the bite force in the mouth.

– The production of 3D printed prostheses has become more common in recent years. The study sought to find the optimal position of the fibrous reinforcement of the prosthesis in the prosthesis and how small an amount of reinforcing material is sufficient to strengthen the prosthesis so that the reinforced prosthesis can withstand bite forces. The reinforcement still has to be added manually today, as there is no 3D printer for dental applications or materials to print the reinforcement directly onto the denture. The research was a preliminary study to address this shortcoming, says Pasi Alander, lecturer and leader of the research team at the Oral Health Research Group of the Turku University of Applied Sciences.

– The back teeth bite harder than the front teeth. These factors make mathematical modelling difficult and can only be done by a multidisciplinary team of dental technicians and engineers. When a fibre reinforcement is added to the prosthesis, the modelling is even more challenging because the calculations have to take into account the properties of the two materials in the prosthesis, continues Pasi Alander.

Theory and practice

Researcher Rabia Altunay is fascinated by the application of theoretical research to practice. She is also interested in working with companies in the future.

The Computational Engineering and Analysis (COMEA) research group aims to find solutions to practical problems using modelling and an interdisciplinary research approach. A good example of interdisciplinarity is the development of dental prostheses using modelling. The work combines modelling, additive manufacturing techniques (3D printing) and oral health research.

The dental prosthesis study was part of the already completed “Additive Manufacturing Centre for the Bio- and Pharmaceutical Industry (AMBioPharma)” project, which aims to promote product development of new pharmaceuticals, dentures, medical instruments and test systems using 3D printing. The research is also part of the activities of TICAM, Turku’s innovation hub for advanced manufacturing (www.ticam.fi).

The role of additive manufacturing/3D printing as part of new product development is growing rapidly. The aim of the project is to strengthen the innovation and competitiveness of the bio- and pharmaceutical industry in Southwest Finland in this growing field.

Get to know Research Groups

Read next

-

Press Release

A wetland in Parainen improves the area’s natural values and water quality

A new water protection reservoir designed by Turku University of Applied Sciences has been completed at Sydänperti in Parainen. The wetland is designed to improve the water quality…

-

Press Release

Wearing VR glasses in dental technology teaching – Taking learning to a new level

Something exceptional is happening at Turku UAS: for the first time in their studies, dental technology students get to experience the processing of 3D models in a completely…

-

News

Artificial intelligence is developed to help nurses to reduce their workload

The PROFIT project examines how artificial intelligence could support the work of nurses. The technology developed in the project will be tested with nursing students of Turku UAS.…