Computational Engineering and Analysis (COMEA) was given the opportunity to consider the heating of the Karvetti artificial grass field. In the past, the heating of the artificial grass field has started in January, with snowfalls and severe frosts. The heating of the pitch is intended to ensure year-round use, which is important for football enthusiasts in the area.

Published:

Edited:

Text: by Siiri Welling

Eero Immonen’ s research group was commissioned by the City of Naantali. In 2007, heating pipes were built under the artificial grass pitch to keep the pitch warm from snow in winter. The installation of heating pipes is generally thought to be the lowest-maintenance way to keep the pitch in working order, as removing snow mechanically breaks the rubber granule surface of the artificial turf and can be costly to maintain.

“Our assignment for the City of Naantali was to find out what would be the most optimal way to heat the Karvetti artificial grass field. In previous years, the heating of the pitch has started in January and continued until the end of March. The possibility of snowfall and frost is greatest during this period. We wondered whether it would be possible to start heating the pitch earlier without using more energy,” explains Immonen, head of the COMEA research team and senior lecturer.

The research team started by looking at the process diagrams of the field and how the field is constructed. They then studied the regulations over eight years and considered the snowmelt model. There were uncertainties in the work, as historical data on heating control signals were not available. For example, there was no data on the temperature of the water-glycol mixture circulating in the pipes. Therefore, the research team decided to model also the control signals depending on the air temperature.

“In our study, we pay close attention to the materials and the different layers of the field, four layers in total when snow is taken into account. Below is the stabilizing layer on top of which the pipelines are built. The total depth of the heating system is about 20 centimeters. At the client’s request, we calculated what would happen if the heating system were only ten centimeters deep. It turned out that the same amount of energy could be used on the pitch for as many as ten more days if the heating system was closer to the surface,” says Immonen.

Snow behaviour is complex

The team also found that the flow rates of the water-glycol mixture in different parts of the field were not the same. The three-dimensional flow model shows a variation in flow rates of up to 20%, which affects the heat transfer properties.

The research team’s calculations show that the most sensible way to heat artificial grass pitches is to start the heating season in January, rather than, for example, in November. A lot of energy is needed to melt the snow, which is why a high heating capacity has to be kept for the snowy season. According to Immonen, the result was not surprising in the end.

“On the other hand, we did not test other scenarios to see if, for example, it would be more efficient to start heating in December. We focused only on the comparison between November and January in the optimization. The most important thing about these results is that we were able to create a lightweight computational model with snowmelt that allows us to quickly explore different scenarios,” says Immonen.

It turns out that for the same amount of energy, it would be possible to play as many as ten more days on the pitch if the heating system was closer to the surface.

According to Immonen, the behaviour of snow is complex during melting. It can melt into water and evaporate. So at the moment, the computer has been trained to understand how snow melts. This information can be taken into account for further development, for example, how long it takes for a particular area or part of an area to melt.

“My vision for further research would be to develop software that would combine the weather forecast with the snowmelt model we created. This would allow us to predict how much heating capacity should be used to keep the field melted and operational when needed,” says Immonen.

This could also be an effective way to explore different rules of thumb to support human sensing for energy-efficient heating control. For example, it may turn out that in some predicted inclement weather conditions it is not useful to heat the field at all. The research team is continuing to investigate this issue. The results could be used to optimise other heating systems.

“I believe that a similar modelling strategy could be applied, for example, to optimize heating or ventilation in public spaces in the future,” concludes Immonen.

Get to know the research report.

The article was published on 22.9.2023 on the previous turkuamk.fi website.

Get to know our research

Read next

-

Press Release

Joint research infrastructure funding for Turku higher education institutions from the Research Council of Finland

The NEMESIS research infrastructure collects data related to the state of the environment and maritime safety in the archipelago. NEMESIS, a collaboration between three universities, enables long-term monitoring…

-

CaseNews

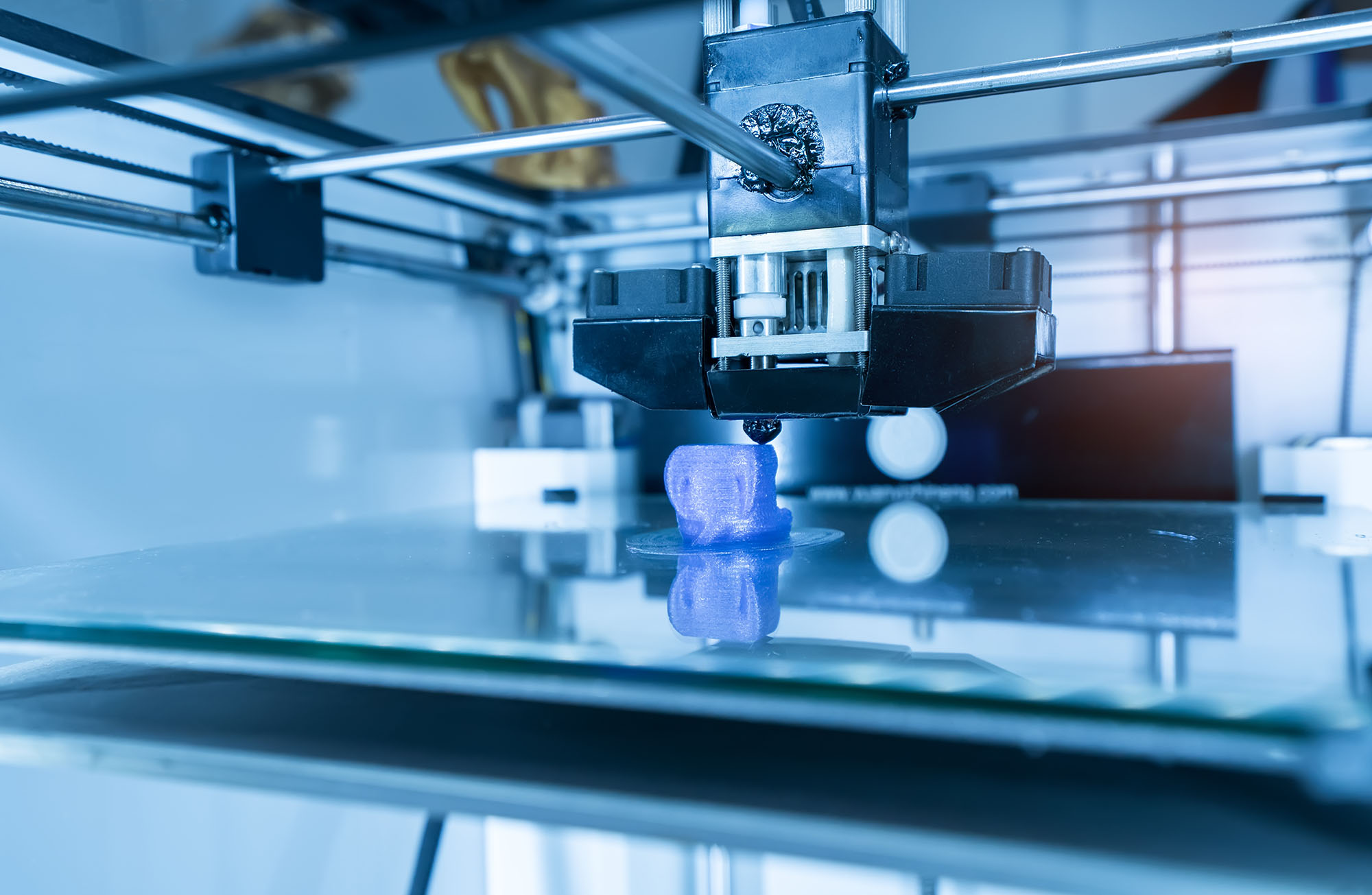

Turku UAS collaborates with EOS Oy, a company specialising in 3D printing

Turku University of Applied Sciences (Turku UAS) and Electro Optical Systems Finland Oy (EOS Oy) are strengthening their cooperation by signing a partnership agreement. In addition, EOS has…

-

Press Release

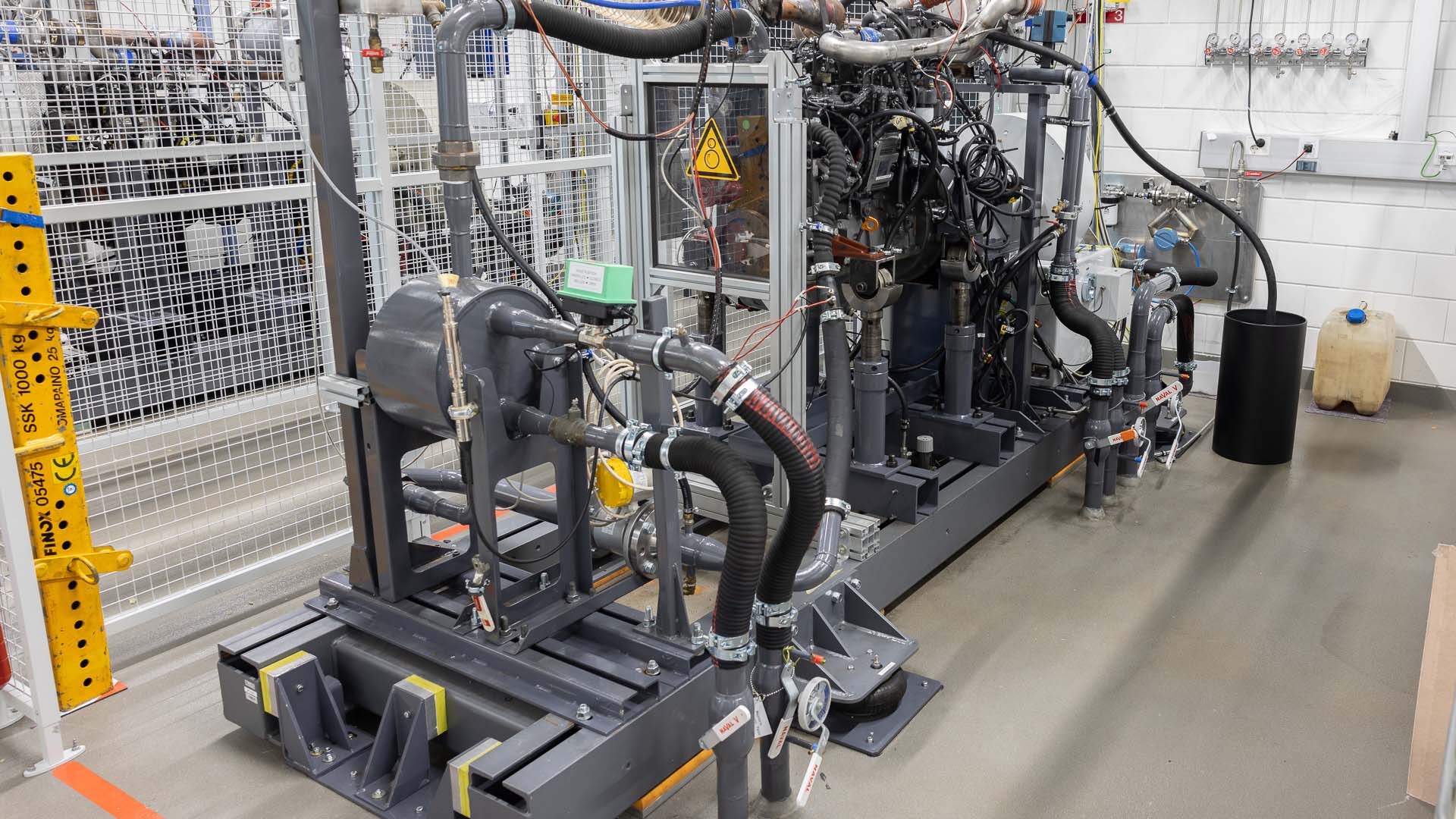

Hydrogen for internal combustion engines

The use of hydrogen as a fuel in internal combustion engines offers significant advantages over the use of hydrogen in fuel cells. A new research project at Turku…